I recently set up what I thought was a mint in box Clementine tipple, only to find that two of its gears were cracked, apparently an age thing similar to zinc-pest. I hope the repair may help someone so I thought I'd share it...

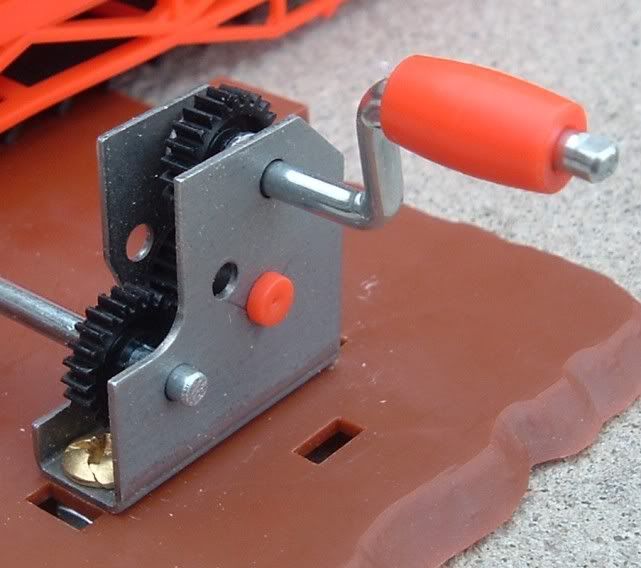

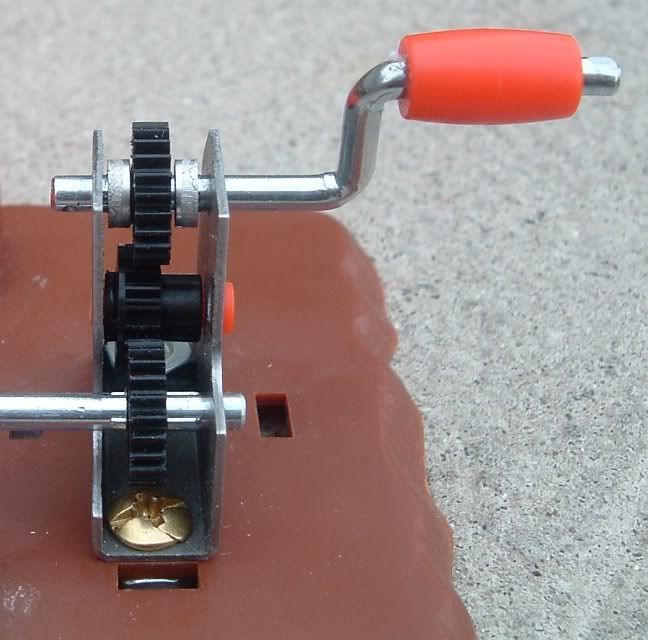

After assuming the fetal position, sucking my thumb and wailing like a school girl, I set about to figure out how to fix this problem, using what I had on hand. I first drilled out the rivets holding the gear tower in place and enlarged the holes to accept 8/32x1/4" bolts and nuts. The one under the conveyor shaft was turned downward to keep the nut from interfering with the gear drive. Using two of the larger gears in an Athearn four wheel diesel truck, I found they fit quite snug in place of the original top and bottom gears. The crank needed only bushings added to keep it centered on the middle original gear, the teeth mesh perfectly.

The middle gear was moved down and back 45 degrees and 1/4" from the original hole by drilling two 1/8" holes exactly opposite each other---much easier with a drill press. After reaming them slightly, the original pin and gear were re-installed into the new holes. A bit of hot glue on either side of the head of the pin holds it securely in place. I then re-installed the gear tower, pushing the lower conveyor shaft gear to the left 'til it aligned with the middle gear.

Now I be all happy dispensing M&Ms through the Christmas holiday...and doing it without greatly affecting the original piece. I find it interesting that, after 35+ years in the hobby, there was as much satisfaction getting this thing running as any number of much more realistic and prototypical scenic vistas and building projects I've done.

No comments:

Post a Comment