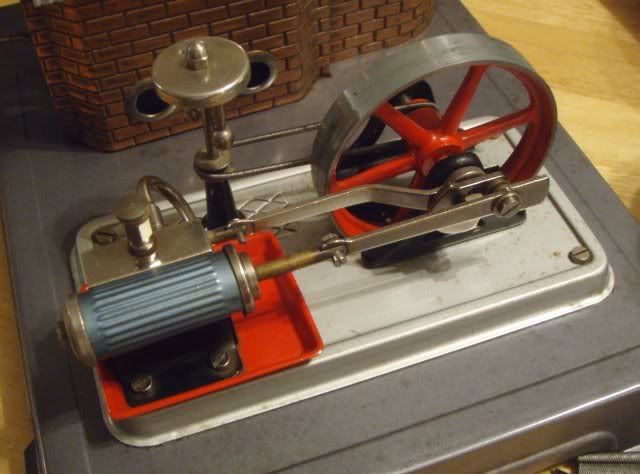

I did manage to repair the whistle using a piece of brass tubing that fit tightly around the whistle pipe. I filed a bird mouth into it, then tapped the two halves together...it is now much stronger than stock and nearly invisible to all but a trained eye. The spring belt for the ball governor was stretched a bit, I tightened that by cutting out about 3/8" and rejoining the ends. After a rub down with WD40, it's starting to look pretty sharp...

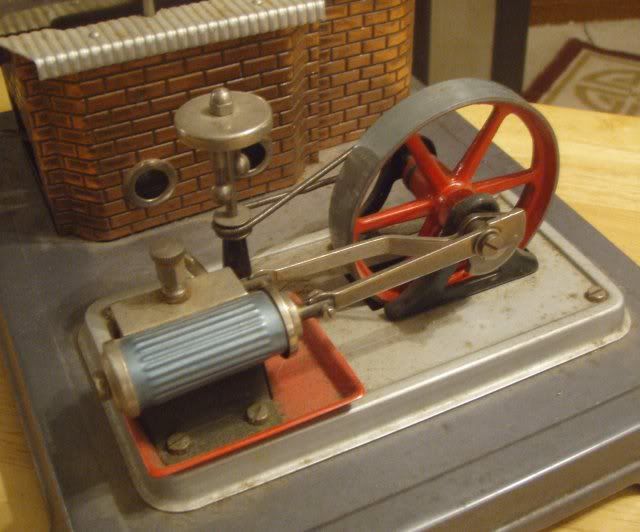

Before...

...after.

The repaired whistle...

...now to find some Esbit tablets so I can fire this puppy up...

2 comments:

Congratulations for a good job done there, sir... :)

The modelism problems of this kind... are like the chess game: they say it helps at thinking development,makes you a good improver and so on.

Thank you...I buffed up the finish last night, giving it a nice shine without making it too bright or removing the patina of a used engine. I'll post pictures of that on Monday.

One of the blessings God has shown me in my modeling is that He made me perfectly capable of figuring out things like this---if only I apply myself, practice a bit of patience, and stop running to online hobby shops every time I need a part. My beloved likes how I figure these things out while trying to watch how much I spend on my hobbies.

Post a Comment